License to Connect

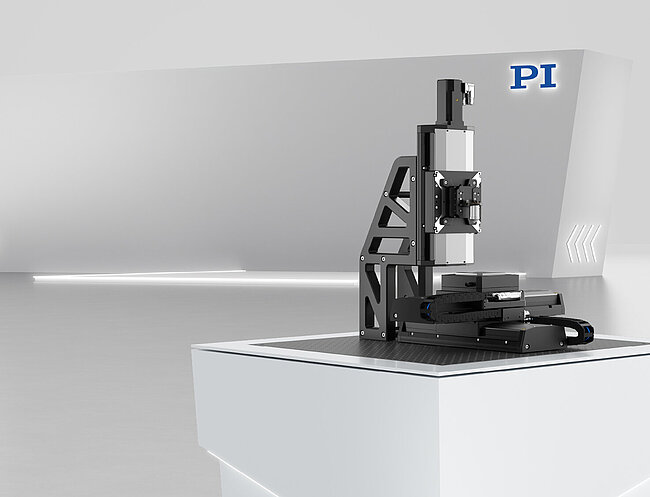

Thanks to the immense transmission capacity and low energy consumption, optical communication is penetrating ever deeper layers of communication networks. Servers are increasingly being connected via glass fibers and also within computers more and more functionalities are being transferred to the medium of light. Placing optical components on silicon semiconductors and creating optical connections are recurring process steps in the production and quality assurance of silicon photonic components (SiPh) and photonic integrated circuits (PICs). Often, transverse tolerances of well below 50 nm are required. Therefore, precision, velocity, and a high degree of automation of the alignment are indispensable for the functionality and cost of manufacturing SiPh and PICs. PI's tried and tested active alignment systems are faster than conventional methods by up to two orders of magnitude and they help to make this critical process economically viable. Starting from quality assurance for optical devices/elements at wafer level up to the final assembly, PI offers complete solutions for different chip designs, formats, and tasks.